™

™

The Ceramext™ Technology

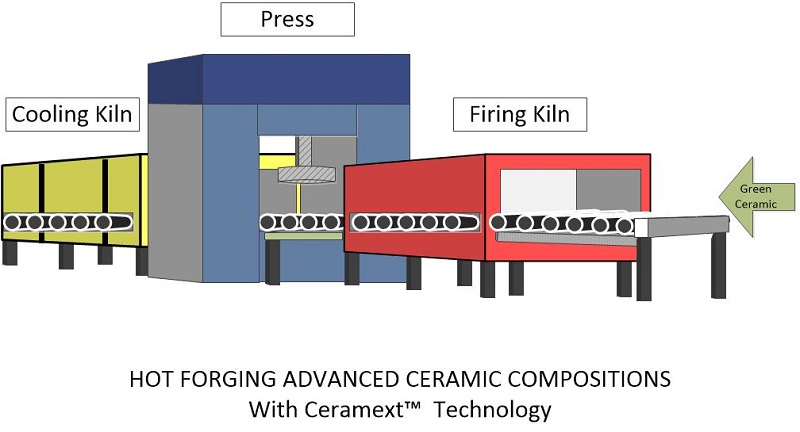

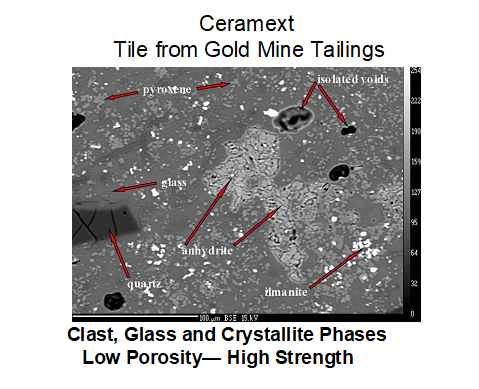

This method of ceramic production relies upon the plastic nature of certain materials that have been heated to about 1000°C, partially melted, and then pressed with about 1000-2000 psi. Generally, a cold steel die is used and as that die slightly expands from the heat of the ceramic, it facilitates the ejection of the hot-forged tile. With minor modifications, conventional green ceramic presses and electric or gas roller kilns can be used for hot forging. The raw materials for these ceramics can originate from most mine tailings, quarry fines, biomass ash, coal fly ash, or other waste materials. Porcelain quality tiles can be made by only screening raw materials, without the expensive grinding and spray drying steps. No binders are required and up to 100% of the waste material can be used. New advanced ceramic compositions using this hot-forging technology have been patented. The new ceramic compositions are impermeable with an MOR generally more than 10,000 psi and excellent facial control without grinding.

Ceramext Hot Forging Methods with conventional equipment – gas, electric, and other kilns – cold presses with minor modifications

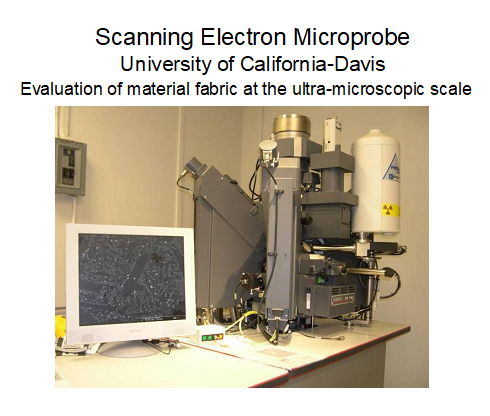

Hundreds of Ceramext tile thin sections have been studied via scanning electron microprobes at the University of California-Davis, other Universities, and the Pacific Northwest National Laboraory.

Contaminates, such as arsenic, if present, are generally rendered inert to leaching or other means by locking them within a stable glassy matrix within the Ceramext composition.